The Recommended Practices (RP) issued by AACE International are widely recognized and have been adopted in estimating and control departments across the process industries. Until recently, the focus of these practices was mainly on capital projects. However, they are now also beginning to cover Maintenance Turnarounds.

As an initial step in covering this important aspect of process plant operation and management, the AACEI has issued the Recommended Practice: Cost Estimate Classification System – As Applied in Maintenance Turnarounds for the Process Industries (112R-20). Senior Cost Engineer and Turnaround Lead at Cleopatra Enterprise Bas Druijf has contributed to this RP.

‘’Cost Engineering was approached by the primary contributor, Gordon Lawrence, to collaborate on this Recommended Practice. As Turnaround Lead, I helped adding, clarifying and reviewing parts of the RP, along with the other co-authors. The result is an RP that is carried by stakeholders from across the industry.’’

– Bas Druijf, Turnaround Lead at Cleopatra Enterprise

The fellow authors for this recommended practice are Gordon Lawrence (Primary Contributor), Carlos Pina, John Hollmann, Dave Kyle, Larry Dysert and Jeffery Borowicz.

How does the Cost Estimate Classification System work for Turnarounds?

The Cost Estimate Classification System as recommended by the AACE International maps the phases and stages of cost estimating together with a generic scope definition maturity and quality matrix, which can be applied across a wide variety of industries and scope content. This specific recommended practice provides guidelines for applying the same principles of the Cost Estimate Classification System specifically to maintenance turnarounds for the process industries (i.e., cost estimates that are used to evaluate, approve, and/or fund projects or turnarounds).

“The Turnaround world is moving towards industry-wide standardization of work processes. Cost estimating was traditionally a very strong discipline for greenfield projects and now maintenance turnarounds are moving in a similar direction. This Recommended Practice helps both to standardize work processes and to take cost estimating for turnarounds to the next level. It gives industry professionals a common language, which they can always fall back on.”

– Bas Druijf, Turnaround Lead at Cleopatra Enterprise

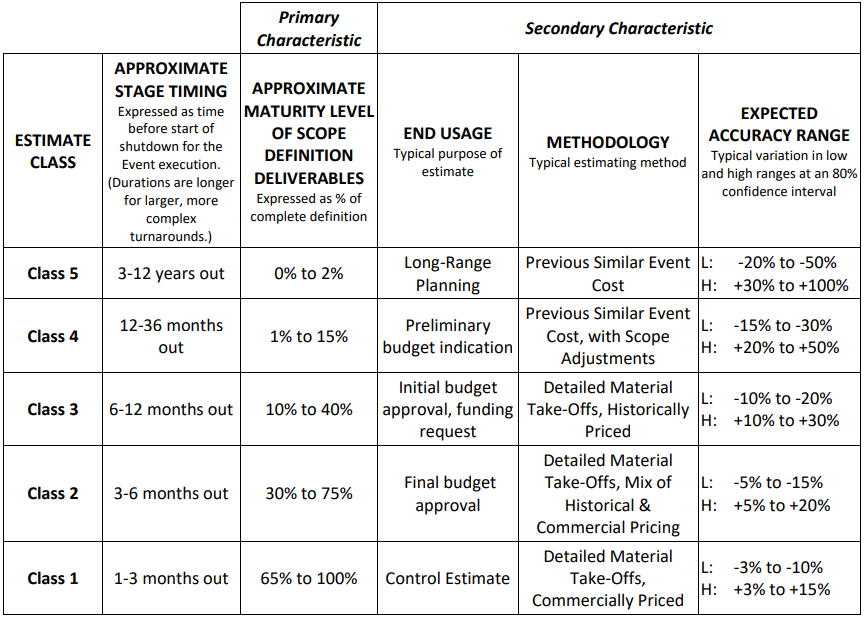

The Cost Estimate Classification Matrix

A purpose of cost estimate classification is to align the estimating process with the turnaround stage-gate scope development and decision-making processes. In capital projects, the length of each stage is a function of the work required to be completed in that stage. The culmination of each stage is a cost estimate, with the estimates getting more accurate with each succeeding stage as risks are treated. Differences from the system used for capital projects include the fact that the length of each stage is (more or less) fixed, based on the amount of time remaining until the turnaround starts. It is not dependent on how far preparation and planning have progressed.

Below you can find the estimate classification system that is specific to maintenance turnarounds in the process industries.

*Cost Estimate Classification Matrix for Maintenance Turnarounds in the Process Industries

This matrix supplements the generic cost estimate classification by mapping the extend and maturity of estimate input information (turnaround preparation & planning definition deliverables) against the class of estimate. The matrix can result in improved communications among all the stakeholders involved with preparing, evaluating, and using turnaround cost estimates specifically for the process industries.

Are you interested to learn more about the recommended practice? AACE members can read the full article. If you’re not a member of the AACE, you can read the sample article.

Do you want to know more about the recommended practice, cost estimating for maintenance turnarounds or our innovative turnaround project controls solution Cleopatra Enterprise? Then please contact us.

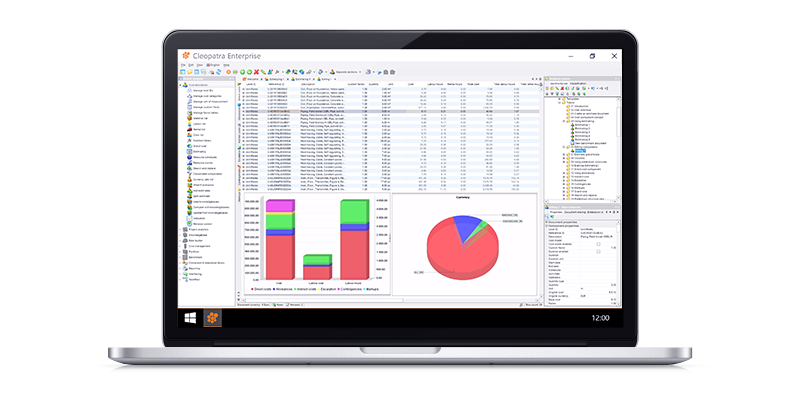

Turnaround Estimating & Budgeting

Cleopatra Enterprise Software